Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue. #dies

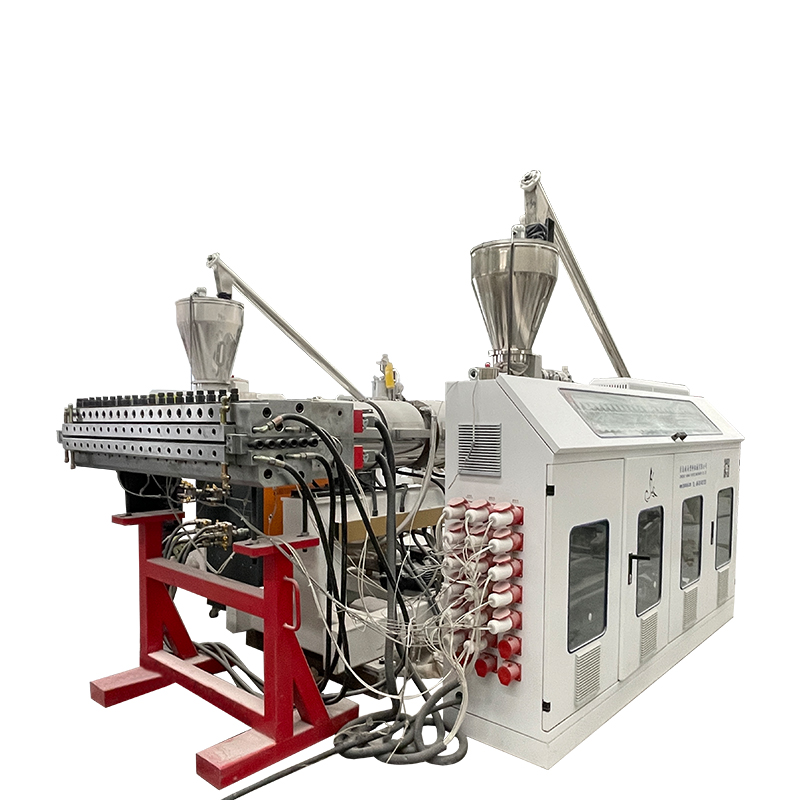

One of the most common problems extrusion plants have is flow shifting in the die tooling, especially after starting up. This can occur even when the run history and setup documents are followed and painstakingly reviewed to the letter. What should be a quick changeover turns into the dreaded scrap nightmare. What went wrong? Plastic Extrusion Cooling System

Sharing knowledge in tool building has historically been taboo. Toolmakers had their little notebook of cheat sheets on land ratios and what drawdown to use with each material. In the end, each tool made from any given tool shop was different. Fast forward and shops are run differently, with most shops running toward one common standard. More literature on tool design is available than in the past, so what is causing the flow shift?

If you start up with a dry profile die, you may wind up having flow instability, which could lead to a host to quality issues. Photo: Matthew Naitove

Let’s troubleshoot and look at the steps which may be causing the flow shift.

Before starting up, lubricate all components of the tooling while hung on the extruder.

Lubricating the die (arrow pointing to the wall to be lubricated) will sometimes improve drag flow and eliminate flow shift. Photo: Tim Groth

Ok, so what if the pressure, melt temperature, die land and heater bands all check out, but the dreaded flow shift happens anyway. There is one more thing to do, which many times will stop flow shift: Lubricate the tooling.

The cavity of a streamline plate does not fill equally because the channel lengths are different, with varying lengths of drag flow. The bigger the tool, the larger the cavity to fill and the greater the potential for problems. Lubricate all components of the tooling while hung on the extruder, before starting up. The initial pressure will be reduced but will increase and reach a stabilization point. Many times, the improved drag flow will eliminate the flow shift issue.

ABOUT THE AUTHOR: Tim Groth has more than 37 years of hands-on extrusion experience, specializing in design for extrudability, tooling design, troubleshooting, material selection, plant setup, training of engineers and setup technicians, and practicing Lean Manufacturing principles. He is currently director of engineering for consulting company Extrusion Solutions North LLC, Hastings, Minn. Contact: 651-357-0814; timtgroth@gmail.com.

Almost all extrusion processes pass melt through wire-mesh screens on the way to the die to provide filtering and improved mixing.

When a profile is not being extruded to the tolerances of previous runs, the die is often suspect—but the real problem may be the heaters. Learn the five heater-band principles before you do any profile die work.

With everyone struggling to find talent, there are ways to reduce operator interaction with the process by applying some lean manufacturing principles.

Plastic Extrusion Factory © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]