Oliver Ballam and Pat Manley demystify boat electrics and explain various types of electrical connectors and their uses on board

Signal wire connectors allow a permanent joint to be made. Credit: Fernhurst Credit: Fernhurst Pre Insulated Terminals

Signal wire connectors make a permanent joint between two or three small diameter signal wires.

Use ‘Eton 23’ or ‘Scotchlok’ type connectors that are gel-filled and seal automatically when the joint is made.

Signal wire connectors are readily attainable from specialist suppliers online.

They have the advantage that they’re designed especially for small-diameter signal wire, such as that used for instrument connections, and are light enough not to need direct support. They are also very easy to fit but not removable.

As we have shown previously, using heat-shrinking tubing is an effective way of insulating a connection.

Heat-shrink tubing is put over the joint and heated using an electric hot air gun (a hairdryer is too cold). Credit: Fernhurst

Some heat-shrink tubing is coated internally with adhesive, which melts when heated. This makes a very corrosion-proof joint.

Where it’s difficult to apply conventional insulation, such as a sleeve, liquid insulation is a very convenient alternative.

This is painted on and the required thickness is built up in layers.

Liquid electrical tape. Credit: Fernhurst

This is very convenient on the connections at the back of small plugs and sockets.

To allow a mast to be un-stepped, cables running down it must have connectors at its base.

These connectors are often a cause of problems due to corrosion, but there are ways of minimising this.

These are available in a number of different forms. The plug and socket have a ‘waterproof’ joint which, in time, will probably allow water to enter the pins and cables.

Waterproof deck plug and socket. Credit: Fernhurst

Annual cleaning of the contacts is a good idea, as is some form of physical protection from damage to the cables.

This method is the quickest to connect/disconnect and so is suitable for places that would need to be disconnected regularly (for example, on a trailer-sailer mast).

Pat Manley and Oliver Ballam demystify boat electrics, starting with switches and relays

Pat Manley and Oliver Ballam demystify boat electrics and explain how to use and make secure electrical wiring connections

After mid-Atlantic battery failure, John Willis decides it’s time to upgrade his battery bank and electrics

Even when you’ve done all your normal pre-departure checks, sometimes the engine still just won’t start. If you have ever…

An alternative to a deck plug is to lead the cables through the deck, using waterproof deck glands.

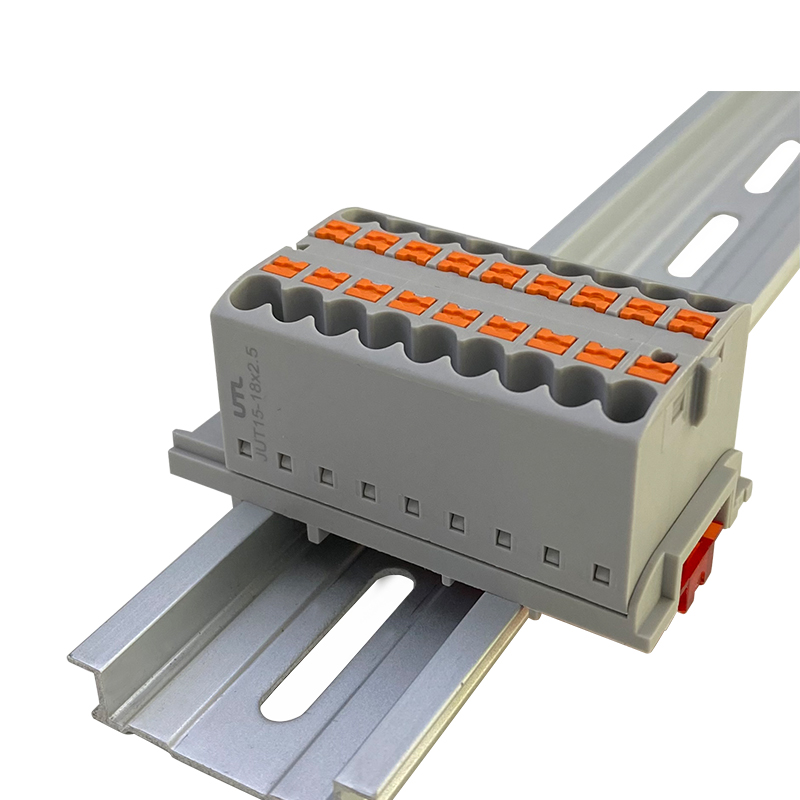

The connections are then made inside the boat using some form of terminal.

Through deck gland. Credit: Fernhurst

This method keeps the connections in a far less corrosive atmosphere, with more space for spare cable to be kept and connections to be made.

In this set-up, a curved large-diameter pipe passes through the deck.

All the cables are run through the pipe so that connections may be made inside the cabin.

Swan-neck deck pipe. Credit: Fernhurst

While not absolutely waterproof, only large quantities of ‘green water’ passing over the foredeck will allow any to leak below.

If this occurs the pipe can be sealed with temporary sealant or a cloth.

The advantage is that it’s very easy to thread the cables through the deck, and nothing needs to be undone.

If there are lots of cables this uses the least space on deck and, if correctly fitted, gives the best physical protection to the cables.

No deck joints are needed for keel-stepped masts, as the cables exit the mast below the deck.

However, it is common for water to leak through the wiring in keel-stepped masts.

Careful sealing at the top entry of the wires and/or a drip loop inside the mast above decks are possible cures for this.

1. Gather the wires and the connector. Don’t strip the wires.

2. Insert the wires into the connector as far as they’ll go.

3. Put the connector into the jaws of the pliers.

4. Squeeze the pliers: the connector will pierce the wires’ insulation to make a good connection and seal the joint automatically with grease.

Read more articles from this series:

Understanding boat electrics: switches and relays

Understanding electrical wiring connections for boats

The third edition of Essential Boat Electrics (Fernhurst Books, £16.99) is available at fernhurstbooks.com.

Written by Oliver Ballam and the late Pat Manley, it’s a practical guide – with simple language and clear diagrams – to allow owners to tackle electrical jobs on board.

There are tutorials, from wiring a circuit, understanding switches and relays to troubleshooting electrical faults, all using easy-to-follow photo sequences.

The book also looks at tasks such as choosing solar panels and batteries and connecting navigational instruments.

Buy Essential Boat Electrics from Amazon (UK)

Buy Essential Boat Electrics from Amazon (US)

Buy Essential Boat Electrics from Foyles (UK)

Buy Essential Boat Electrics from Waterstones (UK)

Buy Essential Boat Electrics from Google Play

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

Follow us on Facebook, Instagram and Twitter

Get every issue of PBO on Android, iPhone, iPad or desktop

Crimp Terminal Connector The boat owner's ultimate guide to wood, the best coastal cruisers under 40ft, laying up – top tips to beat the bug, sailing around every island in England and Wales... and more!